About the Elliott West Wet Weather Treatment Station

Learn more about this upgrade project, combined sewer systems and how to find contract information.

Frequently asked questions

This project will bring the facility into compliance with updated, stricter regulations. EWWTS has not always achieved full compliance under West Point Treatment Plant's National Pollutant Discharge Elimination System (NPDES) permit. This permit allows West Point and its facilities to release wastewater into bodies of water and contains requirements that ensure that operations maintain water quality standards.

The Department of Ecology (Ecology) issues and enforces the NPDES permit. Ecology is currently updating West Point’s NPDES permit.

As we upgrade EWWTS to meet these updated regulations, we are reflecting on what we have learned over the last 20 years. This includes correcting flaws in the original design and learning from operator experiences. We are also updating to include industry-leading technologies such as those used in the recently completed Georgetown Wet Weather Treatment Station. Furthermore, we are assessing climate change modeling for King County to assess how this new facility can solve two things: adapt to the way climate change will alter Puget Sound’s environment and use renewable and clean power.

Project benefits include:

- Better water quality in Elliott Bay

- Full compliance of EWWTS with West Point Treatment Plant’s NPDES Permit

- Reduced untreated CSO discharges

Once the upgrade project is complete, Elliott West will use screening, ballasted sedimentation, and Ultraviolet (UV) disinfection. The screening process utilizes mechanical screens to remove large debris, such as tree branches and toilet paper, from wastewater. Ballasted sedimentation is a treatment method where chemical and polymer are added to wastewater to form flocculated or “clumped” particles with suspended solids, a specialized sand (called ballasts) are then used to allow flocculated particles to attach to it, and a series of settling tubes or plates are used to settle these solids out of wastewater. This is done by running wastewater through two channels or “trains” that consist of a series of tanks for chemical, polymer and sand to interact with wastewater solids. This part of the process removes at least 80% of the suspended solids and other pollutant bonded to the suspended solids.

After this, wastewater moves to the next process: UV disinfection. Here, wastewater flows through one of a few channels that contain several UV banks, each of which contains multiple UV lamps. The banks sit in the channel allowing wastewater to flow around the UV lamps. There are many UV lamps submerged in wastewater to ensure complete exposure of wastewater to high intensity of UV radiation. The UV light disinfects wastewater, inactivating the microscopic pathogens that may pose a health risk to people and wildlife.

To see how Elliott West’s technology will function, you can watch our video about how the technology at the Georgetown Wet Weather Treatment Station works.

Where has the advanced primary treatment technology planned for the Elliott West Wet Weather Treatment Station been used successfully?

The Georgetown Wet Weather Treatment Station has been utilizing this method of treatment since it began operations in November of 2022. So far, Georgetown has kept more than 32 million gallons of polluted stormwater and wastewater from reaching the Duwamish River. Additionally, the Bremerton CSO treatment facility has successfully implemented this technology since 2003. Learn more about the technology used at the Bremerton CSO treatment facility- ballasted sedimentation and UV disinfection.

The upgraded EWWTS facility will need to achieve more stringent water quality standards to meet full compliance under the NPDES permit.

To accomplish this, our project team worked with operations and maintenance staff to identify facility upgrade options that would best meet the NPDES permit standards.

King County considered different criteria to select the best upgrade method. These criteria include:

- Environmental and social impacts

- Operations and maintenance needs

- Lessons learned from the design and operation of Wastewater Treatment Division’s newest CSO facility: Georgetown Wet Weather Station

- Schedule and cost impacts

The selected upgrade method at EWWTS will include improvements to the current facility and construction of a new, larger facility on the parcel directly south, which is also owned by King County. The larger facility is required for new technology and for additional storage capacity. EWWTS will treat the same amount of sewage and stormwater after the upgrades are completed.

We are currently designing the EWWTS upgrades. The design will follow the best alternative that we identified to meet full compliance with the NPDES permit. Once we have the shell of a design, there will be opportunities to provide input on design features such as:

- Facility architecture aesthetics

- Facility landscaping

- Identifying reasonable solutions for construction impacts

We anticipate that design workshops will occur in late 2024. From there, King County will address community concerns and refine the design concept in 2025 and 2026. The design process is expected to last through 2027. Construction will immediately follow.

Much of Seattle was built using a combined sewer system. A combined system uses the same set of pipes to carry both sewage and stormwater. In the neighborhoods around EWWTS, this combination goes to the West Point Treatment Plant in Magnolia to be treated.

During heavy rain, pipes can fill with stormwater that runs off roofs, driveways, and streets. When the system is overwhelmed, it is designed to overflow into waterways. This prevents sewer backups into homes and businesses. These overflows are called combined sewer overflows, or CSOs. EWWTS helps reduce untreated overflows into Elliott Bay by treating stormwater and wastewater during heavy rain.

This project will utilize a collaborative delivery method known as General Contractor/Construction Manager (GC/CM). This differs from the Design-Bid-Build (DBB) project delivery method in several ways.

Using DBB delivery, a design consultant is hired to help design the project, then a construction contractor is selected to build the project through a competitive bidding process. With GC/CM delivery, the construction contractor is brought in earlier to provide input during the design process. GC/CM delivery can reduce constructability challenges and reduce risks for all parties helping to deliver the project.

Please visit King County’s Upcoming contract opportunities page for procurement-related updates.

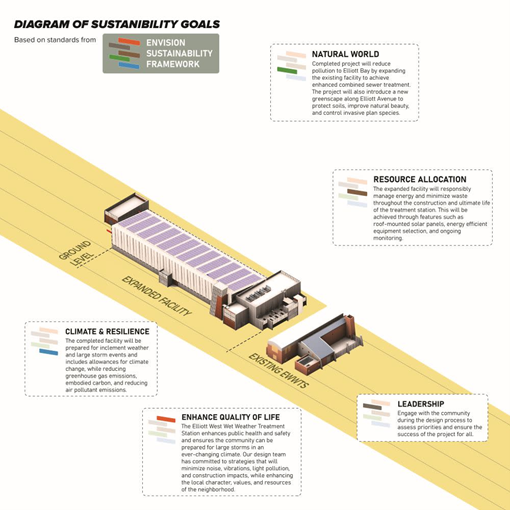

What is Envision?

Envision is a sustainability rating system developed by the Institute for Sustainable Infrastructure (ISI). It assesses infrastructure projects across five categories:

- Quality of Life

- Leadership

- Resource Allocation

- Natural World

- Climate and Resilience

Projects are rated from Verified to Platinum, with Platinum being the highest level of achievement in sustainable and resilient infrastructure.

View of existing and expanded treatment facility with sustainability goals based on the envision framework.

The EWWTS project is actively pursuing Envision Platinum certification, demonstrating King County’s commitment to sustainable infrastructure. Key sustainability and resilience strategies include (but are not limited to):

- Climate adaptation and risk reduction integrated into design and operations

- Energy-efficient systems and potential use of renewable energy sources

- Water quality protection through advanced treatment technologies

- Community and interested party engagement to ensure equitable outcomes

- Habitat preservation and restoration to support local ecosystems

- Lifecycle cost analysis and materials reuse to minimize environmental impact

Protecting water quality in Elliott Bay

The Elliott West Wet Weather Treatment Station (EWWTS) is being upgraded to meet updated National Pollutant Discharge Elimination System permit requirements from the Washington State Department of Ecology. This permit helps make sure that water discharged from the EWWTS during heavy rain events meet federal and state water quality standards.

Upgrading wastewater treatment for compliance and environmental protection

To meet the updated permit requirements, the project will make the wastewater treatment station work better by installing a new screening system, a high-rate clarification system for solids removal, and UV disinfection. These additions will catch debris, remove solids, and kill harmful bacteria in the water. If these changes are not made, WTD would be at risk of not complying with its permit, which may lead to fines and untreated water entering Elliott Bay during heavy rain events. This could harm public health and marine life, pollute the water, and affect nearby parks.

Adapting the station for future weather challenges

We are designing the expanded station to handle weather changes brought on by a shifting climate, especially during severe storms. New pumps will reliably move water into the treatment facility. We have set aside additional onsite space for more treatment equipment in case incoming flows continue to increase. By planning ahead, we will make it easier to add advanced cleaning equipment if needed, ensuring the station remains resilient and adapts to future changes in our community and environment.

This upgrade will help protect water quality, keep our communities safe, and take care of the environment for future generations

Translate

Translate